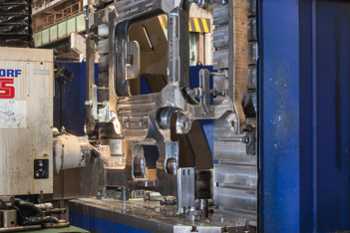

- Specialization in fabrication of fixtures and jigs for production and machining of weldments, castings and sheet metal products

- Manufacture of wood and plastic patterns for manual and machine moulding

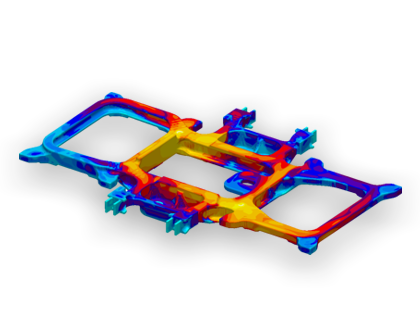

- Design of steel castings in the weight range of 5–5000 kg

Pattern production:

- Wood and plastic pattern facilities for manual and machine moulding

- Pattern design in Solid Edge 3D CAD, milling programming in CAM PowerMILL

- CNC machine for high-speed milling with table 4 x 2 m

- Production of dummy parts and moulds for laminate, composite, and ABS parts

- Customized single-part orders and prototypes

Melting equipment

Selection of Produced Steel Grades:

42 2643.5, E260 -450 -MSC1, E300- 520 -MSC1, 422643.5, 42 2650.1, 2660.5 42 42 2660.6, 422707.9, 42 279.5

GE 300, 42 2709.6, 422712.5, 42 2713.5, 42 2719.5, GRADE 350, GS 45, GE 240, GP 240 GH, GS 52, GRADE C, 20L-III, A2, A4, GE280, GE230, GE320, B2M1C, 20GL, 20GFL

GS 21Mn5V, GS 20Mn5N, GS20Mn5V, G20Mn5 + QT, B50E54D3, GRADE 90-60, 2172-21, GP 240GH, Fe G 520

GS-25CrMo4V, GS 42CrMo4N, GS 42CrMo4V, WC6, 2225-25, 42CrMo4 + QT, 10A, WC4, GS- 35 CrMoV, 30NiCrMo8

Moulding Shop and Core Shop

moulding boxes 1000 x 800 x 300 x 300 mm; capacity ca 250 moulds per shift; castings 5 to 150 kg each.

moulding boxes 1250 x 1250/1400/1600; capacity ca 50–60 moulds per shift; castings 80 to 600 kg each;

moulding with or without flasks; customized, small-lot and serial production with the capacity of 3000 castings per year; capacity ca 350 tons of castings per month; castings 100 to 150 kg each

capacity ca 250 tons of castings per month; castings 100 to 12,000 kg each.

Fettling Shop

The company continues to invest in new tools and equipment required in order to provide high quality of welding processes and heat treatment. These processes also ensure significant reduction of scrap rates and optimize acquisition costs.

Fettling Technologies:

- shot-blasting systems

- heat-treatment furnaces

- tempering furnaces

- argon, plasma and carbon welding

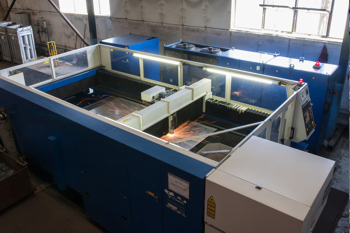

Sheet-cutting equipment; laser and acetylene.

Numerous machining centres of various types and sizes; machining accuracy up to ±0.02 mm.

Various welding aggregates, fixtures/jigs and positioners.

Painting equipment for surface treatment.